Efficiency and safety have become integral pillars of success for warehouse management. A lot of...

14 Trends in Logistics & Warehousing To Look For

Continuously evolving technology provides industries with more opportunities for success. As consumer expectations change, businesses must adapt to the dynamic market with elements like real-time data collection, sustainable practices, and safety precautions.

Staying on top of the trends in logistics and warehousing will ensure your business is a hub of innovation. Read through the many emerging technologies that will support you on this journey to excellence.

Robotics

Automated robots transform warehouses by handling tasks like picking, packing, and sorting. These machines improve efficiency and accuracy, reducing the demand for manual labor. Robotics technology integrates with warehouse management systems. Warehouses see faster turnaround times and fewer errors to meet high consumer demands and reduce operational costs.

Artificial Intelligence (AI)

AI algorithms analyze vast amounts of data to create quickly informed decisions. In warehouses, AI-driven systems manage inventory and forecast needs. They ensure that stock levels match demand patterns.

AI also enhances customer service with chatbots and virtual assistants. These tools provide instant support and information. AI’s role continues to expand, offering smarter logistics solutions.

Blockchain Technology

Transparency, security, and a trustworthy foundation in supply chains are essential. The blockchain system prevents tampering and fraud by tracking products from origin to destination. It offers real-time visibility and accountability. Smart contracts within blockchain automate processes for streamlined operations.

Elastic Logistics

Elastic logistics adapts to fluctuating demands. Companies can scale operations up or down swiftly during seasonal peaks and unexpected surges. This approach relies on real-time data and advanced analytics to predict demand and adjust resources accordingly.

Third-party logistics providers offer scalable solutions; they can handle warehousing, transportation, and distribution needs. Elastic logistics ensures efficiency and customer satisfaction in dynamic markets.

Cloud Computing

Cloud-based platforms store and process vast amounts of information and offer real-time access to data from anywhere. With accessible collaboration, warehouses receive scalable and flexible solutions.

Companies expand storage and processing capabilities by implementing advanced analytics and machine learning applications. It drives innovation and efficiency in logistics operations.

Supply Chain Digitization

Digital tools minimize errors and strengthen accuracy over manual systems. IoT devices collect and transmit data in real time, providing valuable insights into inventory levels and shipment statuses.

Additionally, digital twins create virtual replicas of physical assets, allowing businesses to create scenario simulations and optimize their processes accordingly. The shift toward digitalization provides end-to-end visibility and control over supply chains that improve decision-making and efficiency.

Green Logistics

More and more companies are learning the importance of sustainable practices. Energy-efficient equipment that minimizes resource consumption, electric vehicles for transportation fleets, and recycling and waste management practices reduce their carbon footprint. Green logistics will continue to rise to establish a more sustainable future.

Omnichannel Warehousing

Forming multiple sales channels into a single, cohesive strategy is what omnichannel warehousing is all about. Businesses can offer a better customer experience across online and offline platforms. Furthermore, they can improve inventory visibility and fulfill orders from various locations to keep customers satisfied.

Omnichannel warehousing software systems provide real-time data on inventory levels and order status. These systems connect with various sales channels, including e-commerce sites, brick-and-mortar stores, and mobile apps. As a result, businesses can allocate their inventory efficiently and respond quickly to changing demand.

Predictive Analysis

Technology like predictive analysis uses historical data and advanced algorithms to forecast future trends and events. It helps businesses make informed decisions about inventory management, demand planning, and route optimization.

Predictive analysis works by collecting and analyzing vast amounts of data from various sources. These include sales records, market trends, and weather patterns. Advanced algorithms then identify patterns and correlations within the data. These insights help businesses anticipate demand fluctuations, optimize inventory levels, and plan efficient delivery routes.

Wearable Technology

Devices such as smart glasses, wristbands, and exoskeletons enhance worker productivity and safety. They provide continuous data and guidance, reducing errors and improving efficiency.

The adoption of wearable technology offers several advantages. It enhances worker productivity by providing instant access to information and reducing the need for manual data entry. It improves safety by monitoring health indicators and providing physical support. Additionally, wearable devices contribute to better training and skill development, offering real-time feedback and guidance.

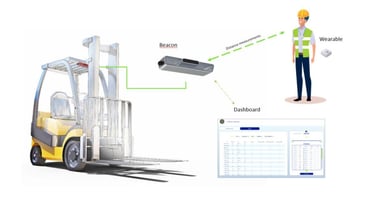

Collision Warning Systems

While looking for warehousing and logistics trends that focus on efficiency, the value of employee safety is especially important. Warehouse safety equipment, like collision warning systems, uses sensors and cameras to detect potential collisions between vehicles, equipment, and personnel. These sensors provide operators with real-time alerts operators to prevent accidents and injuries.

Sensors and cameras capture data on the positions and movements of objects and people. Advanced algorithms analyze this data to identify collision risks. When the system detects a potential collision, it sends alerts to operators, enabling them to take corrective action.

It also minimizes equipment damage and downtime, improving overall operational efficiency. By creating a safer work environment, these systems contribute to higher employee morale and productivity.

Flexible Warehouse Equipment

The ability to reconfigure warehouses easily to accommodate ever-changing demands is incredibly valuable, as it enhances operational agility and efficiency. As such, most businesses can benefit from flexible warehouse equipment.

Workers can reconfigure modular shelving and adjustable racks to fit different product sizes and quantities. Mobile workstations are easy to relocate to support various tasks.

Flexible warehouse equipment also helps businesses manage their inventory more efficiently. Since there isn’t space for excessive stock, the space is more organized and adaptable to manage current demands.

Safety Stock Management

Effective safety stock management helps businesses avoid stockouts and maintain service levels. It works by analyzing historical data and demand patterns to determine optimal safety stock levels.

Advanced software systems automate this process by continuously monitoring inventory levels and adjusting safety stock. These systems consider factors such as lead times, order frequency, and variability in demand.

Multi-Channel Fulfillment

Expanding customer reach and offering multiple purchasing options is a great way to enhance the customer experience. That’s why multi-channel fulfillment maximizes logistics and warehouses. It involves managing and fulfilling orders from multiple sales channels, including online stores, physical locations, and third-party marketplaces.

Businesses can allocate inventory properly and fulfill orders from the most appropriate location. This approach optimizes delivery times and reduces costs. As a result, businesses can thrive in the competitive market.

Complacency doesn’t spark success. Logimate’s goal is to support businesses in logistics and warehousing as they evolve and thrive. We have high-quality technology that will improve your business’s security, safety, and sustainability.