The safe transport and storage of goods is a concern across many industries. As businesses expand,...

How Cable Seals Help Secure Hazardous Materials in Transit

Transporting hazardous materials sits among the highest-risk responsibilities in modern logistics. Chemicals, fuels, pharmaceuticals, radioactive components, and industrial compounds travel through complex supply chains where security failures can endanger lives, damage ecosystems, and shut down operations. After more than a century serving the warehouse safety and security seal market, industry professionals know one thing with certainty: strong physical control still matters.

Below, we’re taking a detail-oriented look at how cable seals help secure hazardous materials in transit. We’ll explain how effective sealing strategies protect these materials and also how organizations cannot afford mistakes with their compliance goals.

The Unique Risks of Hazardous Materials

Hazardous materials pose risks that extend far beyond financial loss. A spill, leak, or unauthorized opening can cause fires, toxic exposure, or environmental contamination. These materials often require specialized handling, labeling, and documentation.

Transport teams must prevent tampering, theft, and accidental access at every point in the journey. Without clear physical safeguards, even a minor lapse can escalate into a serious incident.

Why Physical Security Remains Essential

Digital tools, such as GPS tracking, electronic logs, and monitoring software, help logistics teams gather data, but they do not physically stop interference. Physical security sends an immediate message of control and accountability. A visible seal deters unauthorized access and forces tampering attempts to leave evidence. This clarity allows teams to identify problems before unloading or continued transport creates greater risk.

The security seal market has evolved alongside global transportation for more than 100 years. Early seals focused on simple deterrence, but growing trade volumes and regulatory oversight demanded stronger solutions. Over time, manufacturers improved materials, tensile strength, and tamper-evident features. These advancements came from real-world incidents in warehouses, ports, rail yards, and transit corridors. Today’s sealing strategies reflect decades of hard-earned lessons.

Matching Seal Performance to Hazard Level

Hazardous shipments vary widely in risk. A corrosive chemical demands different controls than a flammable fuel or pharmaceutical compound. Containers, tankers, railcars, and drums all require seals that match their design and exposure level. Selecting an underperforming seal creates vulnerabilities, while selecting an appropriate one strengthens control without disrupting operations.

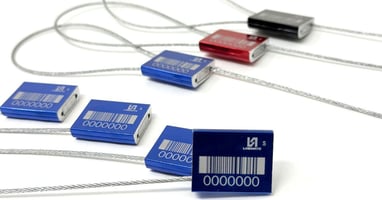

Many organizations rely on cable seals for hazardous material transport because this solution combines strength, flexibility, and clear tamper evidence while accommodating diverse locking points and container designs.

Deterring Unauthorized Access Across Transit Stages

Unauthorized access often occurs during predictable moments: rest stops, border crossings, transfer hubs, and overnight staging. Strong sealing practices force would-be intruders to invest time and tools, increasing detection risk. Drivers and inspectors can quickly identify compromised shipments and prevent unloading or further movement until teams address the issue.

Moreover, regulatory agencies expect hazardous material shippers to demonstrate proactive security measures. Organizations, such as DOT, OSHA, EPA, and international authorities, demand visible proof of control. Proper sealing practices help companies meet these expectations. Inspectors often look first for intact seals because they provide immediate evidence of secure handling.

Strengthening Chain-of-Custody Accountability

Each handoff creates opportunity for error or misconduct. Serialized sealing systems strengthen chain-of-custody processes by linking physical security with documentation. Teams record seal numbers at loading, transfer, and delivery points. This discipline discourages internal shortcuts and makes discrepancies easier to investigate.

Reducing Legal, Financial, and Insurance Exposure

Security failures involving hazardous materials trigger fines, lawsuits, cleanup costs, and reputational damage. Insurers evaluate shipment security practices when determining coverage terms and risk profiles. Organizations that implement consistent sealing protocols reduce exposure and often experience smoother audits, fewer claims, and better long-term risk management outcomes.

Protecting Workers and Public Safety

Hazardous materials endanger more than cargo value. They threaten warehouse employees, drivers, inspectors, emergency responders, and surrounding communities. Sealed containers prevent accidental access during handling and storage. Workers rely on visible security to confirm that contents remain untouched and contained.

Transportation security does not end when a vehicle parks. Hazardous shipments often wait in yards or staging areas before delivery. Sealed containers prevent unauthorized access during these vulnerable periods. Warehouse managers gain greater control over release points and reduce the chance of accidental exposure or theft.

Best Practices for Selecting and Using Seals

Effective sealing requires thoughtful selection and disciplined use. Experienced safety teams evaluate risk level, transport mode, and inspection frequency before choosing solutions.

Some pertinent best practices include:

- Match seal strength to shipment risk

- Train staff on proper installation techniques

- Record seal numbers at every transfer point

- Inspect seals visually before opening

- Secure unused seals to prevent misuse

Training Teams To Reduce Human Error

Even the strongest seal fails when people misuse it. Organizations must train drivers, warehouse staff, and supervisors on correct installation, inspection, and documentation procedures. Ongoing training reinforces accountability and reduces mistakes that undermine security efforts.

Physical seals deliver the greatest value when teams integrate them into a broader security framework. GPS tracking, access controls, audits, and standard operating procedures complement physical safeguards. Physical security offers immediate visual confirmation, while digital tools provide historical insight and traceability.

Supporting Emergency Response and Incident Investigation

When emergencies occur, responders need clarity. Intact seals help responders confirm containment and determine appropriate actions. Evidence of tampering assists investigations and root-cause analysis, allowing organizations to improve future controls.

Customers expect safe, compliant delivery of hazardous materials. Visible security practices demonstrate professionalism and responsibility. Over time, consistent performance builds trust with customers, carriers, regulators, and insurers. Trust strengthens long-term business relationships and competitive positioning.

Modern supply chains involve multiple carriers, third-party logistics providers, and cross-border transfers. Each additional handoff increases exposure risk. Reliable physical security measures provide consistency across different environments, regulations, and operational standards.

Long-Term Value of Proven Physical Security

The warehouse safety and security seal market has endured for more than a century because physical controls continue to deliver results. Strong sealing practices reduce risk, support compliance, and protect people. As hazardous material transit grows more complex, dependable cable seals and physical security remain a cornerstone of safe logistics operations.

Organizations that commit to disciplined sealing strategies protect more than shipments. They protect workers, communities, and long-term business continuity. In hazardous material transport, that commitment defines operational excellence and responsible stewardship. Logimate provides a wealth of resources and products to ensure your material transit efforts remain secure across all sectors. View all our product options today to begin transforming how you package and send hazardous materials.