Securing the movement of goods as they go through the supply chain is non-negotiable. From the...

The 10 Biggest Supply Chain Issues in 2024

Warehouses in the manufacturing industry face constant challenges. Every aspect of sourcing materials, product creation, and transportation must function without a hitch to maintain an efficient supply chain. But there are countless supply chain issues in 2024 affecting operations.

By learning about these difficulties, manufacturing companies can educate themselves and overcome these persistent obstacles. Continue reading below to learn about these issues in-depth and find profitable solutions.

1. Labor Shortages

Labor shortages continue to plague the manufacturing industry. The ongoing struggle to find skilled labor leaves manufacturers scrambling to maintain their production schedules.

This shortage is partly due to the aging workforce and the slow influx of younger workers who possess the necessary skills and training. Additionally, the increased demand for higher wages and better working conditions has put further strain on hiring processes.

Manufacturers are investing in automation and robotics to mitigate these shortages, but these solutions require time and capital investment. Without dedicated and skilled workers, the supply chain cannot operate.

2. Rising Fuel and Energy Costs

Manufacturers rely on fuel and energy to transport raw materials and finished goods. The volatility of global oil markets leads to unpredictable prices.

To combat the fluctuating costs, many manufacturers are switching to renewable energy sources. Wind and solar energy are popular choices that offer significant savings.

However, these strategies take time to develop and ample funds to implement. The initial investment and infrastructure costs create a temporary surge in expenses. For the time being, manufacturing companies must endure the expensive fuel and energy costs to maintain an operational business.

3. Limited Materials

Scarce essential materials make it increasingly difficult to sustain a seamless supply chain. This issue can halt production, cause delays, and deplete funds.

One solution includes strategic stockpiling. This encompasses a reserve of essential materials used during shortages and investing in alternative materials that can perform the same functions as the scarce materials.

Failing to secure a consistent raw material supply chain can lead to lost revenue and reduced market share. Companies might find themselves unable to meet customer demand, resulting in missed sales opportunities and damaged client relationships. Therefore, proactive strategies are essential for long-term sustainability and success.

4. Inflation

The increasing prices of raw materials, coupled with increased labor costs, contribute to overall higher production expenses. Inflation affects purchasing power because it's more challenging to maintain profitability without passing costs onto consumers. This situation is exacerbated when international suppliers are involved, as currency fluctuations can further complicate cost management.

Manufacturers must adopt detailed financial strategies to hedge against inflationary pressures and stabilize their supply chains. Price negotiations and bulk purchasing agreements are just some of the tactics used to combat the adverse effects of inflation.

5. Inconsistent Demands

Inconsistent demand poses challenges for maintaining a balanced supply chain. Market trends shift rapidly because they're easily influenced by consumer preferences, technological advancements, and economic conditions. These fluctuations make it difficult for manufacturers to predict demand accurately and adjust their production schedules accordingly.

Overproduction causes excess inventory, while underproduction can result in stockouts and lost sales. To address this, manufacturers are increasingly relying on real-time data analytics and predictive modeling to anticipate market demands more accurately. Despite these advances, the inherent unpredictability of consumer behavior means that inconsistent demands will remain a persistent issue in the foreseeable future.

6. Higher Consumer Expectations

Consumers today expect faster delivery times, greater product customization, and more sustainable practices. These demands necessitate a more agile and responsive supply chain capable of adapting to changing expectations without compromising quality.

Companies are investing in advanced technology to keep up. However, meeting these higher expectations requires continuous innovation and a willingness to adopt new business models. Manufacturers must stay attuned to consumer trends and be prepared to pivot their strategies to meet evolving demands.

7. Implementing New Technologies

Incorporating new technologies into supply chain operations presents both opportunities and challenges for manufacturers. The adoption of advanced systems streamlines processes, reduces inefficiencies, and leads to significant improvements in overall productivity. These technologies can provide real-time data analytics, predictive maintenance, and enhanced decision-making capabilities that were previously unattainable.

However, the process of integrating these technologies into existing operations is not without its difficulties. One major challenge is getting employees familiar with these advanced systems.

Implement training programs and robust change management strategies for a smooth transition. These initiatives can help employees understand the benefits of new technologies and how to use them efficiently in their daily tasks.

Upgrading machinery is another critical aspect of technological integration. These upgraded machines can significantly reduce downtime, improve product quality, and boost overall operational efficiency. However, the implementation of such advanced machinery also requires a skilled workforce capable of operating and maintaining these tools.

The adjustment period following the introduction of new technology can lead to temporary setbacks in productivity. Employees need time to adapt to new systems, and there may be unforeseen issues that arise during the transition phase. These short-term disruptions can impact production schedules and overall efficiency.

8. Secure Transit

Compromised goods during transit is a recurring issue that has disastrous consequences. This compromise may come in the form of theft, tampering, or damage that poses financial and reputational repercussions.

In 2023, Overhaul documented 1,183 cargo thefts across the United States. The incidents were distributed as follows: 229 in Q1, 208 in Q2, 457 in Q3, and 289 in Q4.

The average value of stolen goods was $586,917. This marks a 9% increase in thefts and a 67% rise in average value from 2022. On average, there were 98.5 thefts per month, resulting in a daily rate of 3.24, up from 2.99 in the previous year.

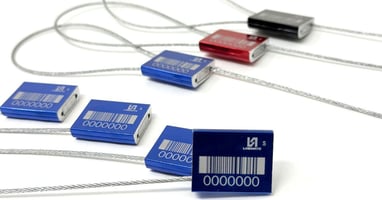

Implement Cable Security Seals

One effective strategy for mitigating these risks is the use of cable security seals. These versatile security devices secure various forms of transport, including trucks, shipping containers, and railcars.

These seals act as a physical deterrent against unauthorized access, offering a visible indication if tampering or an intrusion attempt has occurred. Their strong construction of aluminum and galvanized steel wire establishes tamper-proof products in transit. Manufacturers can strengthen the security of their cargo, so goods always arrive at their destination without interference.

9. Poor Collaborations

Poor partnerships can impede a company’s ability to respond to market demands and optimize operations. Miscommunication and misaligned goals are often the source of operational delays and inefficiencies.

To build strong supplier and partner relationships, transparency and trust are crucial. Manufacturers should invest in platforms that enable real-time communication and data sharing. Next, arrange regular meetings to align objectives and strengthen collaboration.

10. Lack of Data Management

One of the biggest supply chain issues of 2024 is data management. Although there are numerous resources for data analytics and real-time monitoring, some manufacturers fail to leverage this insight.

Effective data management entails collecting, analyzing, and acting on insights to optimize supply chain performance. Investing in data analytics tools and training staff to interpret and utilize this data is essential. A data-driven approach prevents missed opportunities for cost reduction and process improvement.

Now is the time to overcome these supply chain obstacles one at a time. Allow Logimate to improve your process. We’re dedicated to providing warehouses with efficient machinery and safety and security features. Over time, you’ll see notable differences in your warehouse’s productivity and the overall supply chain.